-

tel:

+86 13357917888 -

email:

sales@cxrollformer.com

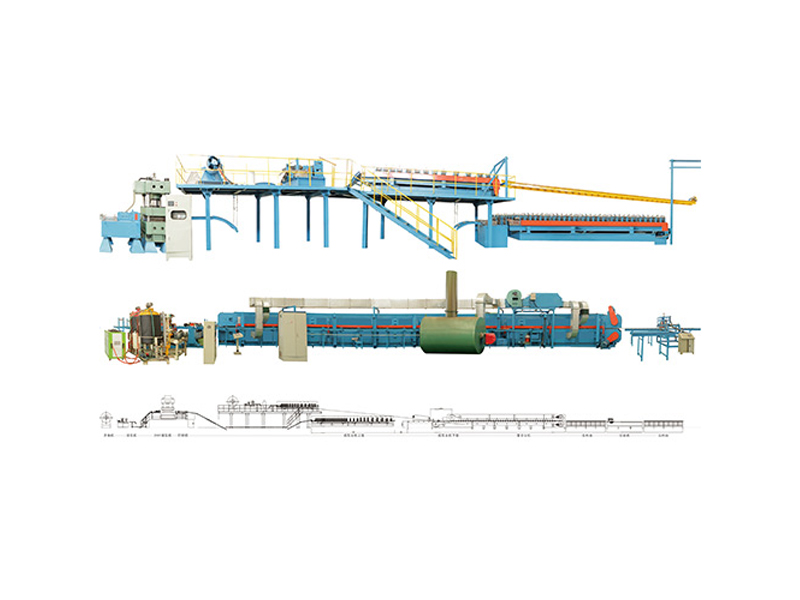

Garage Sectional Door Panel Series Roll Forming Machine

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Min. Order: 1 Set/Sets

Transportation: Ocean

Port: shanghai

Product Attributes

Brand: Chuangxu

Status: New

Applicable Industry: Building Material Shops

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Canada, Egypt, Brazil, Peru, Turkey, Saudi Arabia, United Kingdom, United States, India, Italy, Mexico, France, Russia, Germany, Spain, Morocco, Kenya, Chile, South Africa

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Canada, Egypt, Brazil, Peru, Turkey, Saudi Arabia, United Kingdom, United States, India, Italy, Mexico, France, Russia, Germany, Spain, Kenya, Morocco, Chile, South Africa

Out-of-warranty Service: Online Support

Core Components: Plc

Supply Ability & Additional Information

Transportation: Ocean

Place of Origin: china

Port: shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Packaging & Delivery

Selling Units: Set/Sets

Main component of the line:

|

NO. |

name |

quantity |

|

Main roll former |

|

|

|

1 |

Un-coiler (5 tons ) |

2 |

|

2 |

Embossing and firm machine |

2 |

|

3 |

Automatic feeder and leveler (N.C) |

1 |

|

4 |

Press machine(200ton) |

1 |

|

5 |

Square mould |

1 |

|

6 |

Upper roll former |

1 |

|

7 |

Mark machine (N.C) |

1 |

|

8 |

Down panel roll former |

2(two types) |

|

9 |

Double layer construction platform |

1 |

|

10 |

Double bridge device and conveyor |

1 |

|

11 |

Other conveyor |

1 |

|

12 |

Hydraulic system |

1 |

|

13 |

Electrical control system |

1 |

|

|

|

|

|

2. PRE-HEATING SYSTEM |

|

|

|

1 |

Heating house |

1 |

|

2 |

pre-heating system |

1 |

|

3 |

electrical control system |

1 |

|

|

|

|

|

3.HIGH PRESSURE FOAM MACHINE |

|

|

|

1 |

High pressure continuous foam machine |

1 |

|

2 |

Pursing output device |

1 |

|

3 |

Electrical control system |

1 |

|

NO. |

Name |

Quantity |

|

4. DOUBLE BELT SYSTEM |

|

|

|

1 |

Double belts system(24M) |

1 |

|

2 |

Chain supporting system of two side |

1 |

|

3 |

Side-chain system |

1 |

|

4 |

Heating machine for double belts |

1 |

|

5 |

Electrical control system |

1 |

|

|

|

|

|

5. Thickness and plastic mould |

|

|

|

1 |

Mould & Plastic mould blade |

1 |

|

|

|

|

|

6. CUTTING SYSTEM |

|

|

|

1 |

Cutting saw blade |

1 |

|

2 |

Conveyor with output table |

1 |

|

3 |

Electrical control system |

1 |

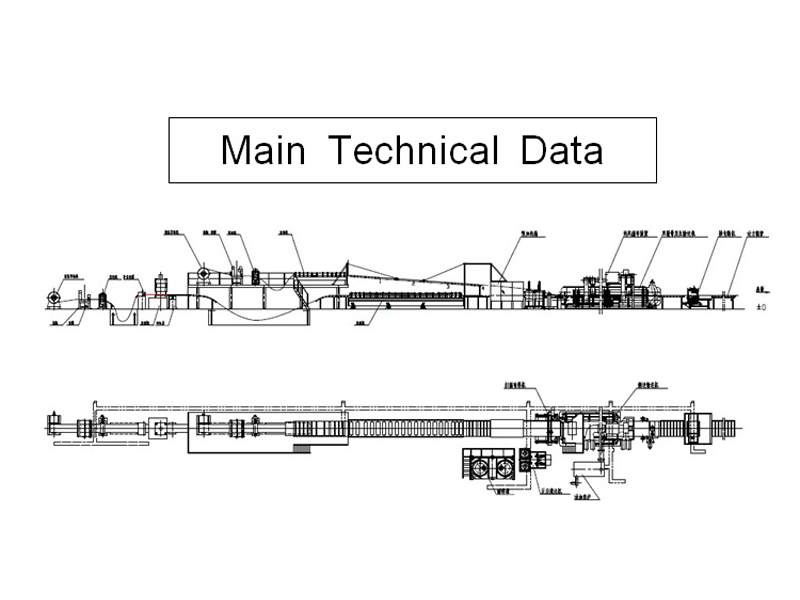

Panel Data

Facing layersmaterial: steel

Thickness to be specified

Panel type:Garage door panel

Dimensions of the final product

widthmin: 400mm

max: 600mm

Thicknessmin: 40mm

max: 60mm

Double belt length: 24m

Plant speed: max.10m/min.

min.2, 5m/min

Typical production range 4-6m/min

(Depending on foam system and cutting time)

Working height: 1.300mm

Height of production building:approx. 6m

Electrical Control System:

Temperature of production building: 15 - 35°C

Operating voltage: 380V

Operating frequency: 50Hz

control voltage: 220V

valve voltage: 24V

Signal voltage: 24V

PLC brand: Delta

|

NO. |

ITEM |

UNIT |

PARAMETERS |

REMARK |

|

|

1 |

PANEL MATERIAL |

TYPES |

|

Pre-painted steel; Aluminum; Platinum |

CUSTOMIZED |

|

Hardness |

MPa |

≤350 |

|||

|

Thickness |

mm |

0.4-0.8 |

|||

|

Coil width |

mm |

≤1250 |

|||

|

Coil ID |

mm |

500.600 |

|||

|

Coil Weight |

T |

5.8.10 |

|||

|

2 |

FOAM MATERIAL |

|

EPS \ POLYURETHANE |

CUSTOMIZED |

|

|

3 |

Length of sandwich panel: |

m |

3-15 |

|

|

|

4 |

Length of sandwich panel: |

mm |

≤1050 |

CUSTOMIZED |

|

|

4 |

Length of sandwich panel: |

mm |

≤200 |

CUSTOMIZED |

|

|

5 |

SPEED OF OUTPUT |

m/min |

3-7 |

|

|

|

6 |

PRESSURE OF FOAM INJECTION |

bar |

150-200 |

|

|

|

7 |

Length of round convey |

m |

21 |

CUSTOMIZED |

|

|

8 |

Controller |

|

PLC INVERTER |

||

|

9 |

Total Power |

Kw |

300 |

||

|

10 |

Overall dimensions |

m |

110x15x5 |

||